Dosimeter badge services for medical, dental, and veterinary businesses

Learn how Radiation Detection Company’s easy-to-use dosimetry solutions can boost the efficiency of your practice.

An extensive radiation safety program is a crucial piece for all businesses that interact with radioactive material. In this article we will detail the principles of radiation safety, as well as the proper creation and maintenance of an effective radiation safety program.

We hope you find this article informative, and as always, we look forward to hearing your feedback!

The main principle of radiation safety is referred to as "ALARA." ALARA is an acronym that stands for "as low as reasonably achievable." This simply means that the goal of a radiation safety program is to keep worker radiation doses as low as possible.

To accomplish this goal of avoiding radiation hazards, there are three basic protective measures to avoid and limit exposure to radioactive materials.

Time refers to the duration spent near a radiation source. The amount of time should be minimized whenever possible, while of course still allowing the worker to accomplish necessary tasks.

Distance refers to the proximity to a radiation source. The amount of distance should be maximized whenever possible. Increasing distance leads to decreasing dose.

Shielding refers to simply putting something between you and the radiation source (whether it be a wall, protective clothing, or other equipment to assist in proper shielding).

Maintaining an environment focused on occupational safety is crucial for all of your radiation workers. Developing and implementing a radiation safety program is a best practice for protecting personnel from ionizing radiation. You'll remember that ionizing radiation includes x-rays and gamma rays (electromagnetic radiation), alpha and beta particles, and neutron radiation.

An effective radiation safety program is usually managed by a qualified expert called a radiation safety officer (RSO). You may also find it valuable to organize a radiation safety committee, which includes the RSO, a management representative, and personnel who work with radiation-producing equipment or are otherwise at risk of occupational exposure.

An effective radiation safety program will also include:

The U.S. Nuclear Regulatory Commission (NRC) has established and maintains dose limits for occupational exposure for people working with radioactive materials. States regulate X-rays and X-ray generating devices to also be in compliance. These limits function as a form of radiation protection for monitoring personnel.

People in contact with radioactive substances during the course of their employment (or those who may be exposed to radiation) normally carry personal dosimeters to capture a measure of radiation emitted during the course of their work. These dosimeters are specifically designed to record and indicate the radiation dose received.

The whole body dosimeter badges are used to monitor exposure to a single occupational worker who is potentially interacting with radioactive materials.

This TLD badge is a single element ring dosimeter for extremities. The ring badge is optimal for those workers whose job functions potentially require their arms or legs to receive a higher exposure.

This TLD badge is fitted with a Velcro strap to be worn around the wrist. The wrist badge is ideal for workers whose arms may receive a higher potential exposure.

Fetal Monitors are available for those who are pregnant to ensure that the fetus does not exceed a significant radiation dose of 500 mrem for the entire gestational period or 50 mrem/month. The badge should be worn close to the embryo/fetus to obtain the most accurate dose.

Area TLD cards can be used to ensure that the public is not being exposed to more than 100 mrem/year from outside a room/building. In addition, they can monitor radiation doses for employees who are potentially occupationally exposed. These TLD cards can be placed in a room where the radiation sources are located, or a room near a source that radiation could potentially reach.

To learn more about Thermoluminescent Dosimeters, please review our recent article "Thermoluminescent Dosimeter [TLD] - Everything You Need to Know"

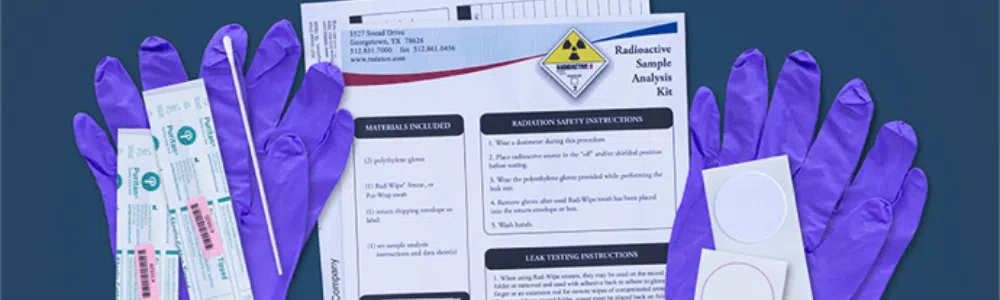

In addition to our wide selection of TLD solutions, we also offer leak tests. Leak tests are wipe test analysis kits that contain everything you need to perform leak tests on sealed radioactive sources to ensure the source is not breached. After you gather the samples, you can mail them back to us, and we will send you a certificate displaying the results within 10 business days of our acquisition of the samples.

Occupational dose is the amount of ionizing radiation exposure received by workers in the course of their employment. A Control Dosimeter plays an integral role in providing an accurate measure of occupational dose. The control badge measures the background radiation dose received during shipment (either to you or back to us) and storage.

To calculate occupational dose, the measurement recorded on the control dosimeter is subtracted from the individual doses recorded on each thermoluminescent dosimeter in the group to arrive at the occupational dose.

The difference of the two measurements is the occupational dose for that radiation worker. Having an accurate measure of occupational radiation ensures the number is within the limit allowed by applicable regulations.

To learn more about the importance of the control dosimeter, please check out one of our most recent articles titled "8 Must-Know Facts About Control Dosimeters."

Radiation Detection Company is dedicated to keeping you and all of your employees safe. We have 75 years of experience providing quality dosimetry service to over 28,000 companies nationwide.

Want to take the next step in getting your organization set up with RDC’s radiation safety products? Please visit our Solutions page to view our full suite of offerings.

We offer a wide range of affordable and comprehensive solutions to fit the needs of any organization, large or small. We understand that choosing a solution can be difficult, which is why our world-class customer service team is happy to provide guidance to help you make the best decision for your company.

As we detailed, radiation exposure risks can be very severe. That's why we've also created a 50 State Guide to Radiation Safety. This complete guide will help you navigate radiation safety requirements for your practice.

Have a question that we did not address in this article? Please reach out to our Customer Care team, and one of our specialists will be happy to assist you.

Learn how Radiation Detection Company’s easy-to-use dosimetry solutions can boost the efficiency of your practice.